Lehigh Hanson, a subsidiary of HeidelbergCement, and Silicon Valley-based materials technology company Fortera announced a collaboration to implement a new type of carbon capture and utilization (CCU) technology in a pilot installation at Lehigh’s Redding, Calif. cement plant.

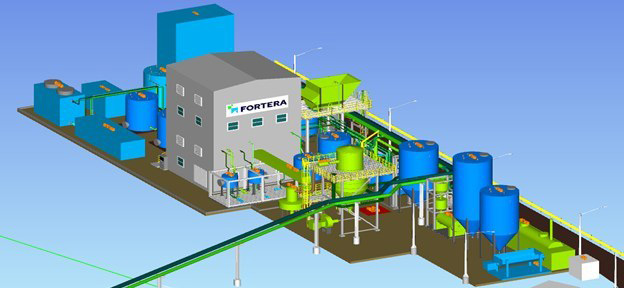

Both companies will work together to construct and operate a small commercial plant where CO2 will be captured from the kiln exhaust and converted into a cementitious material through Fortera’s proprietary recarbonation (ReCarb) process. The process works by tapping into the existing feedstock and equipment at the plant, while production carries on as usual from the quarry to the kiln. Instead of then releasing CO2, the kiln exhaust is captured and mineralized into a cementitious material. The final product can then be co-blended with portland cement and used as a low carbon supplementary cementitious material (SCM) or 100% cementitious binder for preformed materials such as bricks, blocks, and precast structures.

“The Fortera process has been designed to utilize the existing cement infrastructure, from the quarry to the kiln, but with less CO2 emissions, lower energy, and lower processing temperatures – leading to 60% lower CO2 emissions per tonne of product,” said Dr. Ryan Gilliam, CEO and co-founder of Fortera.

The plant will be the first installation of its kind to capture CO2 directly from a cement kiln and convert it to a profitable product. The collaboration with Fortera aims to prove the commercial scalability, the quality of the final product, and the competitive economics of the technology.

“We feel very fortunate to be a part of this exciting project and we are confident that this will be a key step toward our goal of zero net CO2 emissions,” said Dan Fritz, president of Lehigh Hanson’s West Region.